Dual Shaft Shredders

Home » Size Reduction Shredders » Dual Shaft Shredders

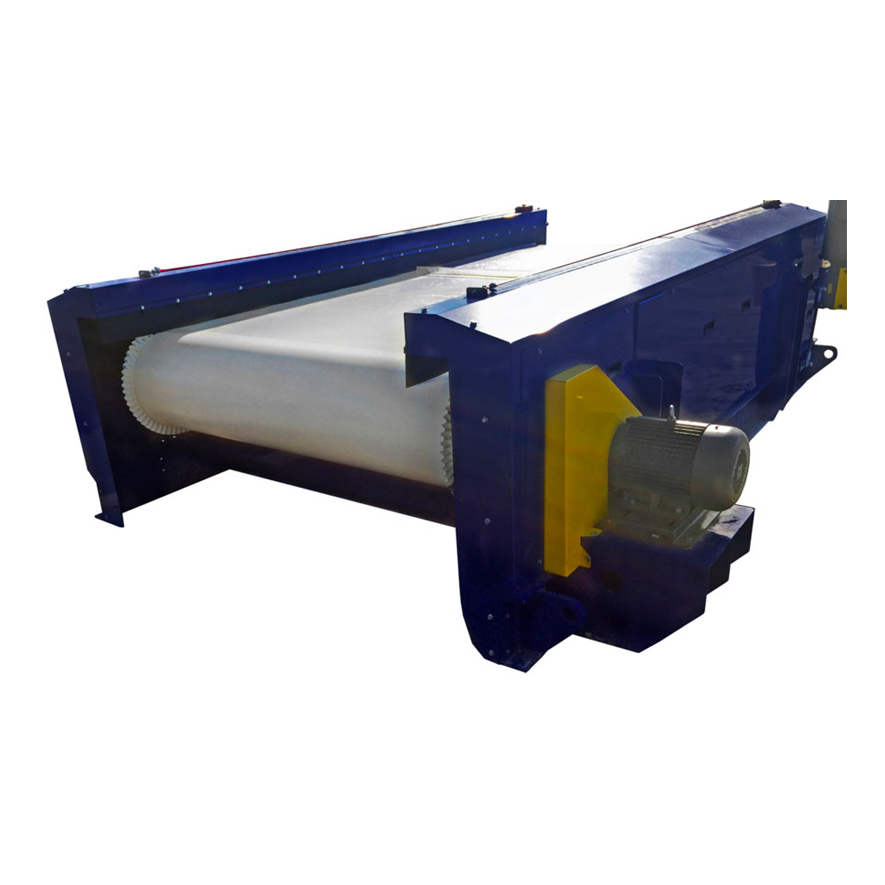

Dual Shaft Shredders utilize two shafts that counter-rotate and are ideal for a variety of destruction and primary size-reduction applications.

Dual Shaft Shredders are often used for document destruction, e-scrap, and product destruction as well as pre-shredding tissue, wood scrap, tires, counterfeit goods, household products, and automotive parts for further processing.

Dual Shaft Shredders offer a variety of cutter configurations to process material, while avoiding jams, to offer high continuous throughput. They may utilize a ram to assist with cutter engagement if the product being shredded has a frictionless exterior.

Dual Shaft Shredders are low-speed, high torque industrial shredders that result in lower heat and dust generation than high-speed, low torque shredders.

Dual Shaft Shredder Features

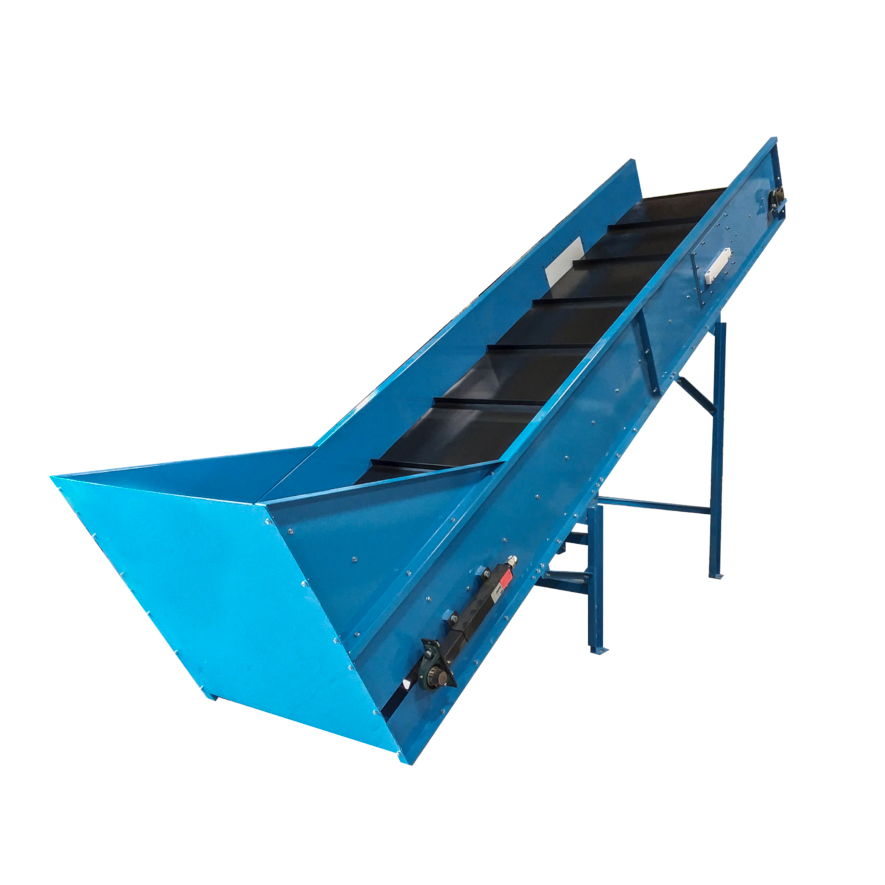

- Custom in-feed hoppers

- Auto reversing PLC driven controls

- Cutter configurations are application specific

- In-line planetary drives for maximum transfer of torque

- Auto shaft reversal improves reliability by preventing overfeeding and damage from unshreddable objects

- Bearing protection prevents shredded contaminants from reaching the bearings

- Built to order for a seamless fit in your system

- UL/CSA rated panels are available

- Individual cleaning fingers

Dual Shaft Shredder Specifications

| MODEL | CHAMBER SIZE | NUMBER OF DRIVES | HORSEPOWER |

|---|---|---|---|

| DS-15 | 16 in x 21 in | 1 | 10 or 15 |

| DS-20 | 24.25 in x 26.5 in | 2 | 20 |

| DS-30 | 23 in x 36 in | 1 | 30 or 40 |

| DS-55 | 24.25 in x 26.5 in | 2 | 45 or 55 |

| DS-60 | 28 in x 38 in | 2 | 55 or 60 |

| DS-75 | 31 in x 48 in | 1 | 50, 60 or 75 |

| DS-125 | 35 in x 50 in | 1 | 100 or 125 |

| DS-150 | 39 in x 60 in | 1 | 150 |

Dual Shaft Shredding System Design

Dual Shaft Shredding Systems are custom built according to each application’s requirements. The stated references and specifications are just guidelines for each machine. Contact an AMOS sales engineer for more information and sizing assistance for your two shaft shredders.