Primary Scrap Tire Shredders

Home » Size Reduction Shredding Applications » Primary Scrap Tire Shredders

Primary Scrap Tire Shredders reduce passenger and truck tires into rough strips to prepare them for further processing once the steel belts have been removed. We are well known for our primary shredding and size reduction equipment, not crumb rubber production equipment, which we do not manufacture.

Primary Scrap Tire Shredders may require a dual shaft shredder or quad shaft shredder depending on your required throughput and particle size. Both are low-speed, high torque industrial shredders manufactured in the U.S.

Primary Scrap Tire Shredders and shredding systems are specifically engineered for your application to ensure you meet your throughput, footprint, and particle size requirements.

PRIMARY SCRAP TIRE SHREDDER FEATURES

- Hex Shafts

- Sealed Bearings

- Overload Protection

- Lockable Disconnect

- Drive Configurations

- Hooked Cutter Profiles

- Hardened Alloy Cutters

PRIMARY SCRAP TIRE SHREDDER USERS

- Landfills

- Insulation

- Agriculture

- Construction

- Manufacturers

- Rubber Recyclers

- Automotive Industry

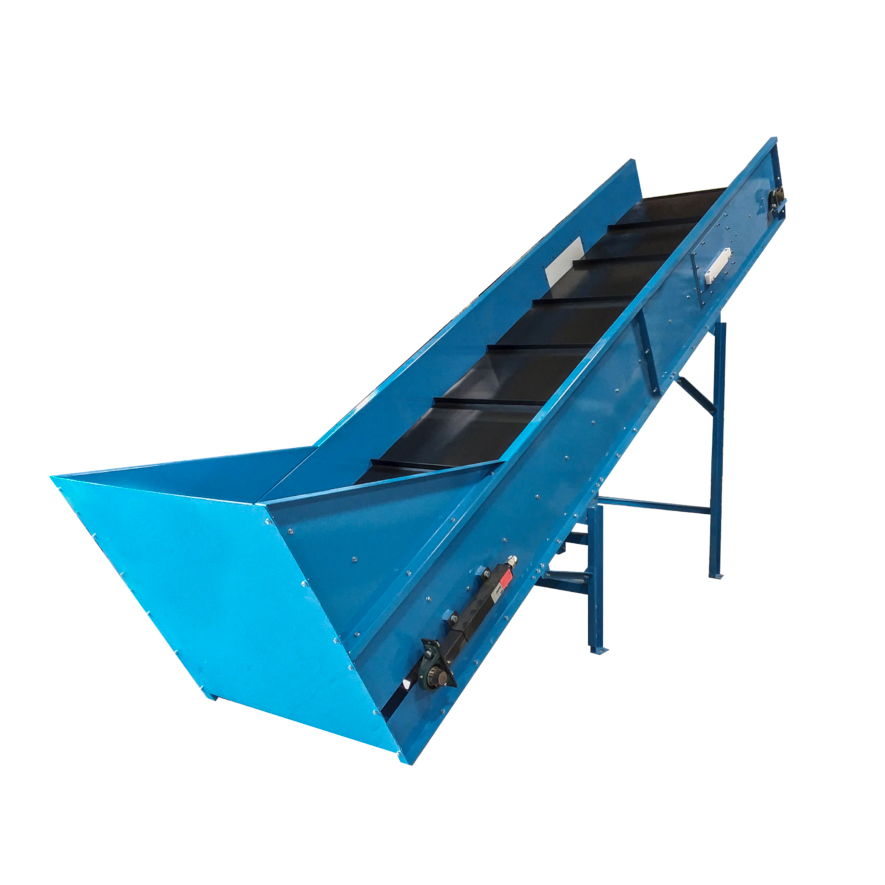

PRIMARY SCRAP TIRE SHREDDING SYSTEMS

- Balers

- Augers

- Conveyors

- Fines Removal

- Metal Detectors

- Custom Hoppers

PRODUCT DESTRUCTION CUSTOMER TESTIMONIAL:

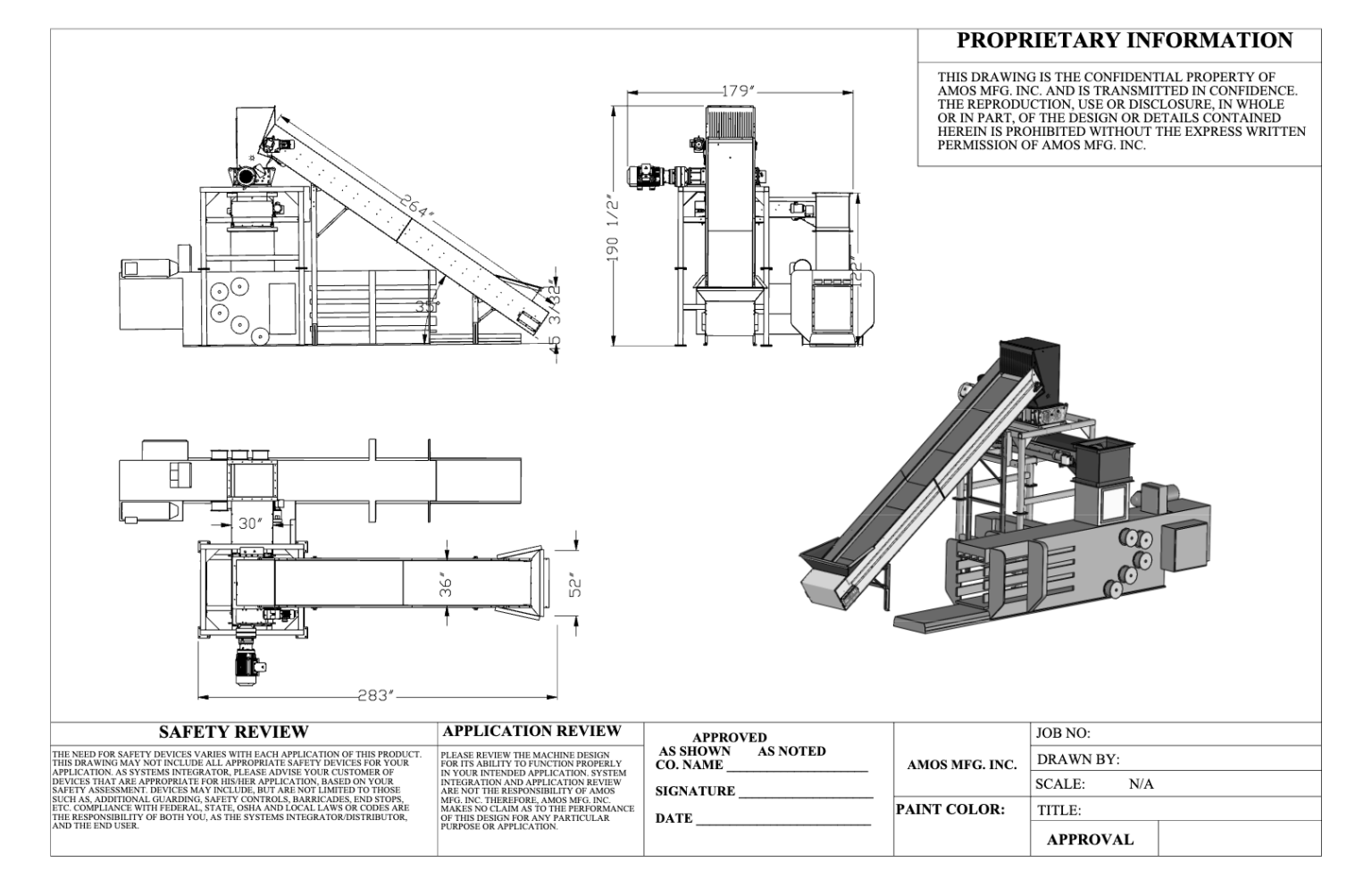

PRIMARY SCRAP TIRE SHREDDER DRAWING